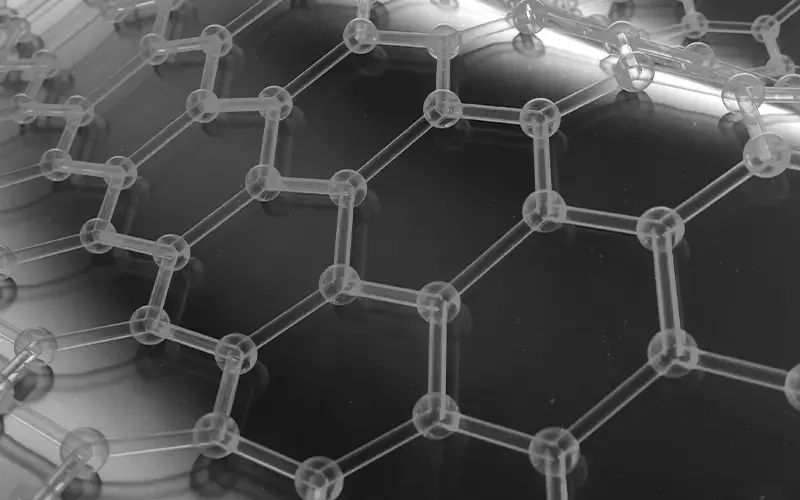

Super Capacitor

- Home /

- New Energy Activated Carbon /

- Super Capacitor

Scene Details

Role of Activated Carbon

Related Product Categories

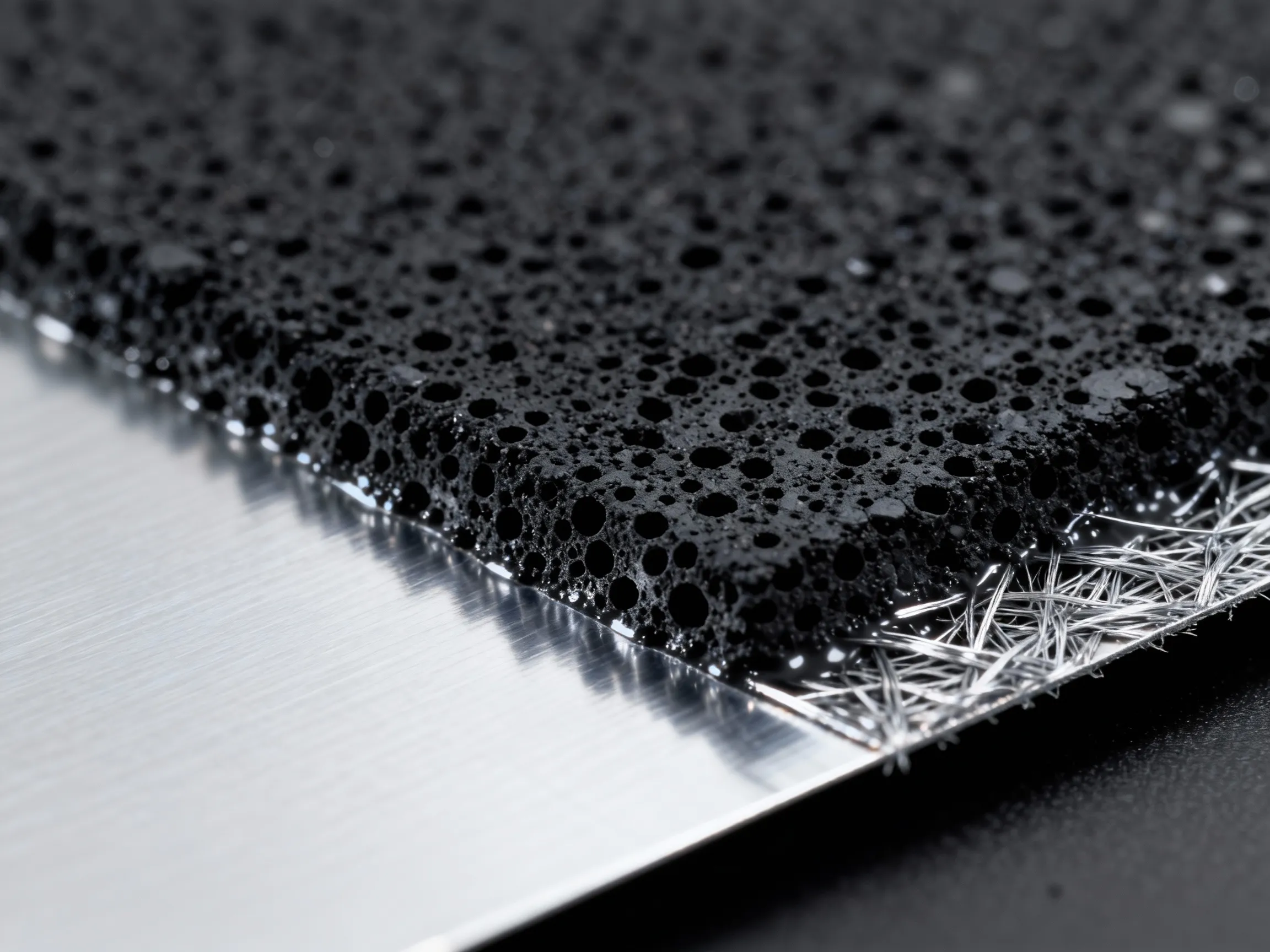

High-Purity Powdered Activated Carbon

The primary form for electrode slurry preparation, offering an ultra-high surface area (>2000 m²/g) and controlled micropores for maximum charge storage.

Coconut Shell Based Activated Carbon

Derived from a pure, renewable source, it provides an ideal, consistent microporous structure essential for high capacitance and stability.

Chemical Activation Activated Carbon

This process (e.g., using KOH) creates a tailored pore network with a high proportion of micropores, optimizing it for superior electrochemical performance.

Specific Solutions

Electrode Manufacturing for Consumer Electronics

Automotive & Transportation Applications

Industrial Energy & Grid Stabilization

Why Choose Us

Electrochemical Grade Specialization

We produce activated carbons engineered specifically for EDL capacitance, with optimized pore size distribution and ultra-high purity.

Customizable Pore Architecture

Our chemical activation expertise allows us to tailor the micro/mesopore ratio to match your specific electrolyte and performance targets.

Batch-to-Batch Consistency

Rigorous quality control ensures identical electrochemical properties in every shipment, which is critical for reliable supercapacitor manufacturing.

Dedicated R&D Partnership

We work closely with clients from the lab scale to production, providing technical data and co-developing solutions for next-generation devices.