Lithium Battery Activated Carbon

- Home /

- New Energy Activated Carbon /

- Lithium Battery Activated Carbon

Scene Details

Role of Activated Carbon

Related Product Categories

High-Purity Powdered Activated Carbon

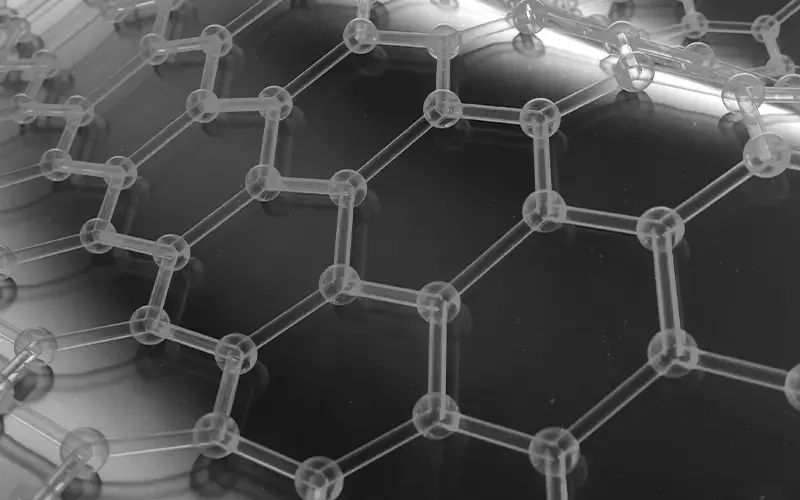

An ultra-fine conductive additive for electrode slurries, enhancing electronic conductivity and electrolyte wetting within the electrode matrix.

Coconut Shell Based Activated Carbon

Offers a consistent, microporous structure and high purity, ideal for sensitive electrochemical applications where impurity control is critical.

Chemical Activation Activated Carbon

Provides a highly tailored, microporous network suitable for applications requiring precise pore size control and maximum surface area.

Wood Based Activated Carbon

Features a broader pore structure, useful in functional layers or components where electrolyte absorption and retention are key.

Specific Solutions

Conductive Additive for Electrodes

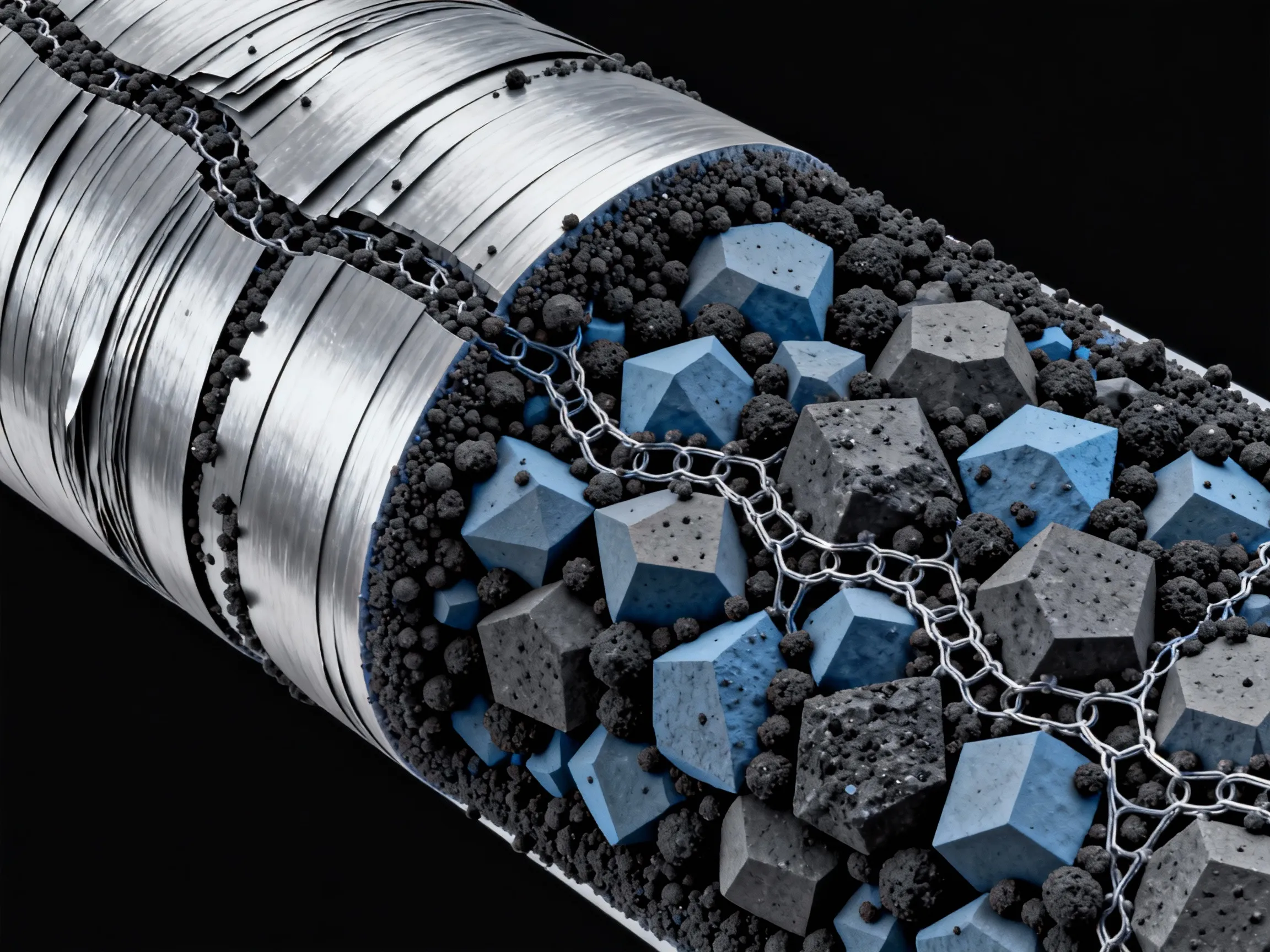

核心部件——混合电极概念的高清横截面示意图。画.webp)

Functional Component in Lithium-Ion Capacitors (LICs)

Safety and Performance Additive

Why Choose Us

Battery-Grade Purity

Our products are manufactured to exceed stringent purity standards, ensuring minimal metallic impurities that can degrade battery performance and safety.

Tailored Pore Engineering

We specialize in customizing pore structure and surface chemistry to meet specific requirements for conductivity, adsorption, or electrolyte interaction.

Proven Electrochemical Stability

Our carbons are validated for long-term stability within aggressive battery electrolyte environments, ensuring consistent performance.

Collaborative Development

We partner closely with battery manufacturers and R&D teams to co-develop and scale new carbon solutions for cutting-edge energy storage designs.