Granular Activated Carbon

- Home /

- Granular Activated Carbon

Classification Introduction

Product Advantages and Characteristics

- Activated carbon (GAC) has a large amount of accessible internal area (up to 5000 m²/g) and thus is capable of removing various types of contaminants (both organic and gaseous) more effectively than other absorbants due to this high surface area.

- The microporous structure of GAC allows for large quantities of contaminants (such as chlorinated solvents, VOCS, and odors) to be absorbed into the carbon, creating a high-efficiency method of purification.

- GAC has excellent mechanical properties, meaning it can handle high loads and extreme temperatures. Due to this, GAC has an extremely long operational life and generates very little wear/dust during continuous operation.

- GAC is offered in many different sizes, and the size of the GAC can easily be adjusted to meet the needs of a specific application. This enables operators of various types of filtration processes to customize their flow rates/contact times based on the filtration medium they are using.

Why Choose Us

Production

Utilizing state-of-the-art activation technologies coupled with strict quality control, our GAC is consistently produced with high levels of purity, and world-class adsorption properties.

Sales

With a globally united and supported supply chain, we are able to meet customer demand with our competitive pricing for prompt and dependable product delivery; and our comprehensive product offerings meet the needs of various industrial segments.

Service

We provide expert technical support, including custom solutions and after-sales support, based on our broad experience in the activated carbon industry to help our customers overcome challenges they face.

Relevant Application Scenarios

Air/Gas Treatment

GAC Adsorption of VOCs and Toxic Gases in Industrial Waste Gas Treatment

GAC adsorbs volatile organic compounds and toxic gases (including ammonia) from the exhaust of factories, reducing the impact of these substances on the environment.

GAC Air Purification in Industrial and Residential/Commercial Settings

GAC removes contaminants and odors from aerosolized particles (i.e. airborne particles) present in industrial and residential/commercial locations to provide a better quality of indoor air.

Biogases Removal of Hydrogen Sulfide Using GAC to Produce Raw Biogas

When used in an anaerobic digester to produce biogas (i.e. methane), GAC helps to remove contaminants such as hydrogen sulfide, so that the produced Methane has greater potential for use as a renewable energy source.

Water Purification

Wastewater Treatment

GAC removes pollutants and chemical constituents from industrial and municipal wastewater to meet reuse and discharge requirements.

Drinking Water Treatment

GAC eliminates chlorine, taste, and odor compounds, to provide you with clean and safe drinking water.

Desalination

GAC pre-treats seawater to remove organic fouling and protect membranes, thus maximizing desalination efficiency.

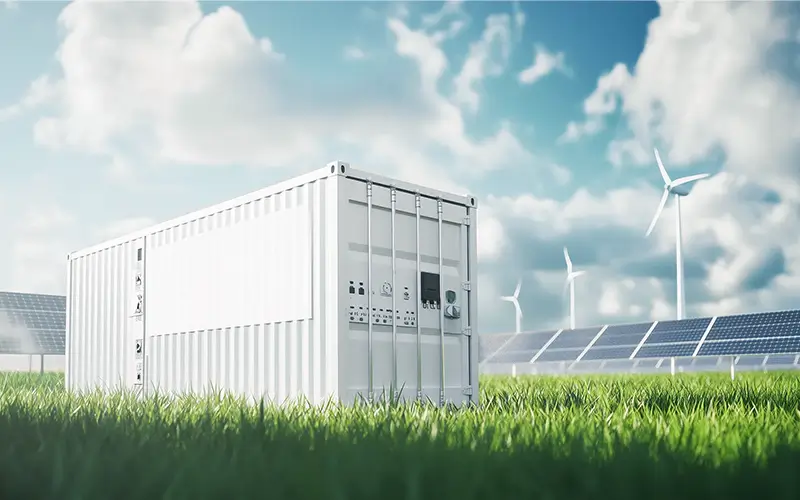

New Energy

Super Capacitor

GAC provides a large enough surface area for energy storage due to its rapid discharge capabilities and extended life span.

Lithium Battery

In addition, GAC can be found within Lithium Battery electrical systems as a means to increase conductivity for optimal battery function.

Personal Protection

GAC provides protection for individuals working in a hazardous environment by trapping harmful substances and making sure that users are not exposed to these substances.

Food & Beverage

Food Decolorization

It adsorbs unwanted colors and contaminants from syrups and oils, ensuring product clarity.

Food Preservation

GAC helps control odors and spoilage agents, extending the freshness of stored food items.

Agriculture

Soil Additive

It binds pesticides and heavy metals, reducing soil contamination and promoting plant growth.

Aquaculture

GAC removes ammonia and organic waste from water, maintaining healthy conditions for aquatic life.

Metal Mining

Medicine

It purifies pharmaceutical products by removing impurities and toxins during manufacturing.

Blood Purification

GAC adsorbs toxins in hemodialysis systems, supporting kidney failure treatments.

Chemical

Desulfurization

It removes sulfur compounds from gases and liquids, reducing corrosion and emissions.

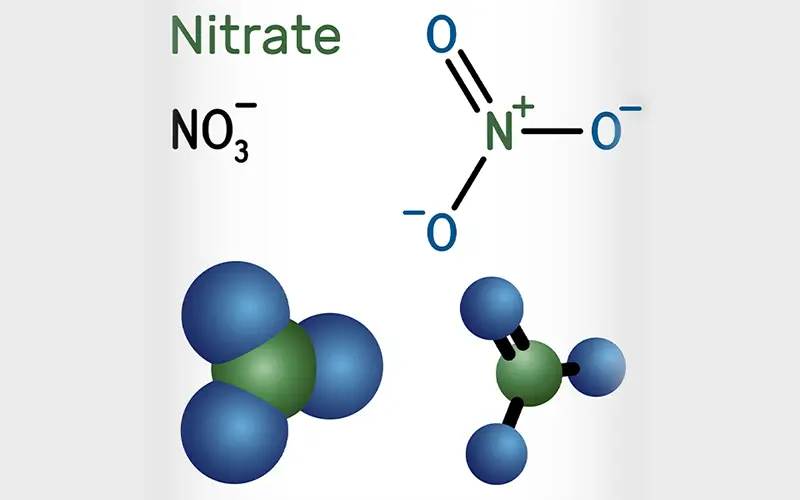

DeNOx

GAC adsorbs nitrogen oxides from exhaust streams, aiding in air pollution control.

Mercury Removal

It captures mercury from flue gases and wastewater, mitigating environmental hazards.

Catalytic

GAC serves as a catalyst support in chemical reactions, enhancing process rates and selectivity.