Chemical Activated Carbon

- Home /

- Chemical Activated Carbon

Classification Introduction

Specific Scenario Details

Desulfurization

Our activated carbon effectively removes hydrogen sulfide (H₂S) and organic sulfur compounds from natural gas, biogas, and process streams, protecting downstream equipment and ensuring product quality through reliable adsorption.

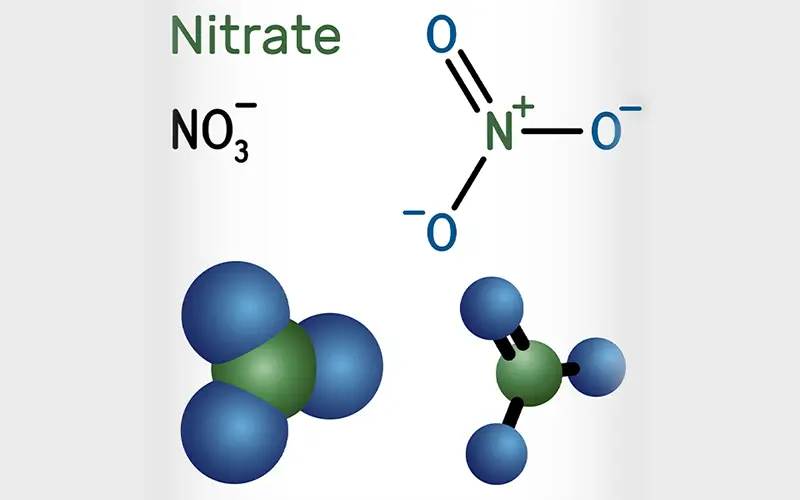

DeNOx

In selective catalytic reduction (SCR) systems, our impregnated activated carbon facilitates the conversion of nitrogen oxides (NOx) into harmless nitrogen and water, helping industrial plants meet stringent emission standards.

Mercury Removal

Specifically designed activated carbon effectively captures elemental and oxidized mercury from flue gases in coal-fired power plants and industrial boilers, ensuring compliance with mercury emission regulations.

Catalytic

Serving as both adsorbent and catalyst support, our activated carbon enables various chemical reactions including phosgene synthesis, vinyl acetate production, and hydrogen peroxide manufacturing with high efficiency.

Why Choose Us

- Application-Specific Formulations: We develop customized activated carbon products with precise pore structures and surface chemistry tailored for specific chemical applications, ensuring optimal performance in your process.

- Proven Technical Performance: Our products undergo rigorous testing in simulated industrial conditions, providing guaranteed performance data for adsorption capacity, catalytic activity, and service life in your specific application.

- Global Technical Support: Our experienced engineering team provides comprehensive technical support from system design to operational optimization, ensuring proper implementation and troubleshooting for complex chemical applications.

Display of Related Product Categories

Honeycomb Activated Carbon

Features monolithic structure with minimal pressure drop, perfect for large-volume flue gas treatment applications requiring efficient mercury removal and low energy consumption.

Chemical Activation Activated Carbon

Provides precisely controlled pore size distribution and high surface area, optimized for catalytic applications and specialized chemical adsorption processes requiring specific porosity.

Impregnated Activated Carbon

Chemically enhanced with specific agents like iodine or potassium iodide for superior mercury removal efficiency, or with other chemicals for specialized catalytic and gas purification applications.

Pelletized Activated Carbon

Offers low pressure drop and high mechanical strength, making it ideal for fixed-bed reactors in desulfurization, DeNOx, and catalytic processes where structural integrity is crucial.