Catalytic Activated Carbon

- Home /

- Chemical Activated Carbon /

- Catalytic Activated Carbon

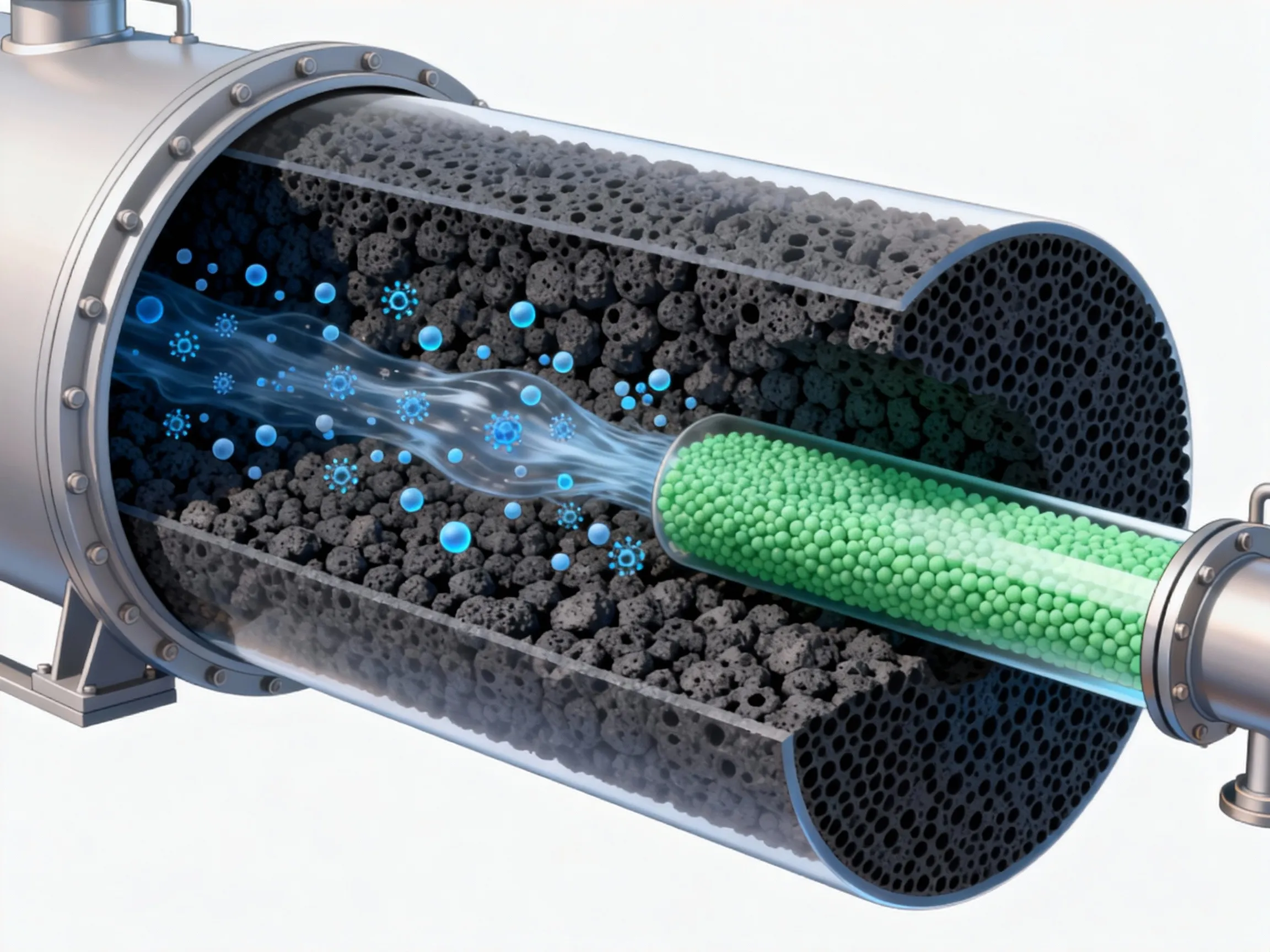

Scene Details

Role of Activated Carbon

Related Product Categories

Catalytic Granular Activated Carbon (GAC)

Designed for fixed-bed reactors in continuous flow systems, such as municipal water treatment for chloramine removal or air purification.

Catalytic Pelletized Activated Carbon

Offers excellent flow characteristics and mechanical strength for use in scrubbers and industrial gas-phase reactors.

Impregnated Catalytic Carbon

A subset where specific catalytic metals or compounds (e.g., potassium permanganate) are added to the carbon to target very specific chemical transformations.

Metal-Supported Catalytic Carbon

Utilizes the carbon as a high-surface-area support for precious or transition metal catalysts, used in specialized chemical synthesis.

Specific Solutions

Municipal Drinking Water: Chloramine & Hydrogen Sulfide Removal

Industrial Air Purification: VOC & Odor Oxidation

Chemical Process & Catalyst Protection

Why Choose Us

Proprietary Catalytic Formulations

We develop and produce specialized catalytic carbons with optimized surface chemistry for high activity and long service life in targeted applications.

Application-Specific Performance Validation

We provide laboratory testing and performance data tailored to your specific contaminant stream, ensuring the selected carbon will deliver the required results.

Expertise in Reactive Adsorption Systems

Our technical team offers deep knowledge in designing systems that leverage both the adsorptive and catalytic properties of carbon for maximum efficiency.

Consistent Quality for Process Reliability

We maintain stringent manufacturing controls to ensure every batch of catalytic carbon delivers predictable and reliable performance in your critical processes.