Mercury Removal Activated Carbon

- Home /

- Chemical Activated Carbon /

- Mercury Removal Activated Carbon

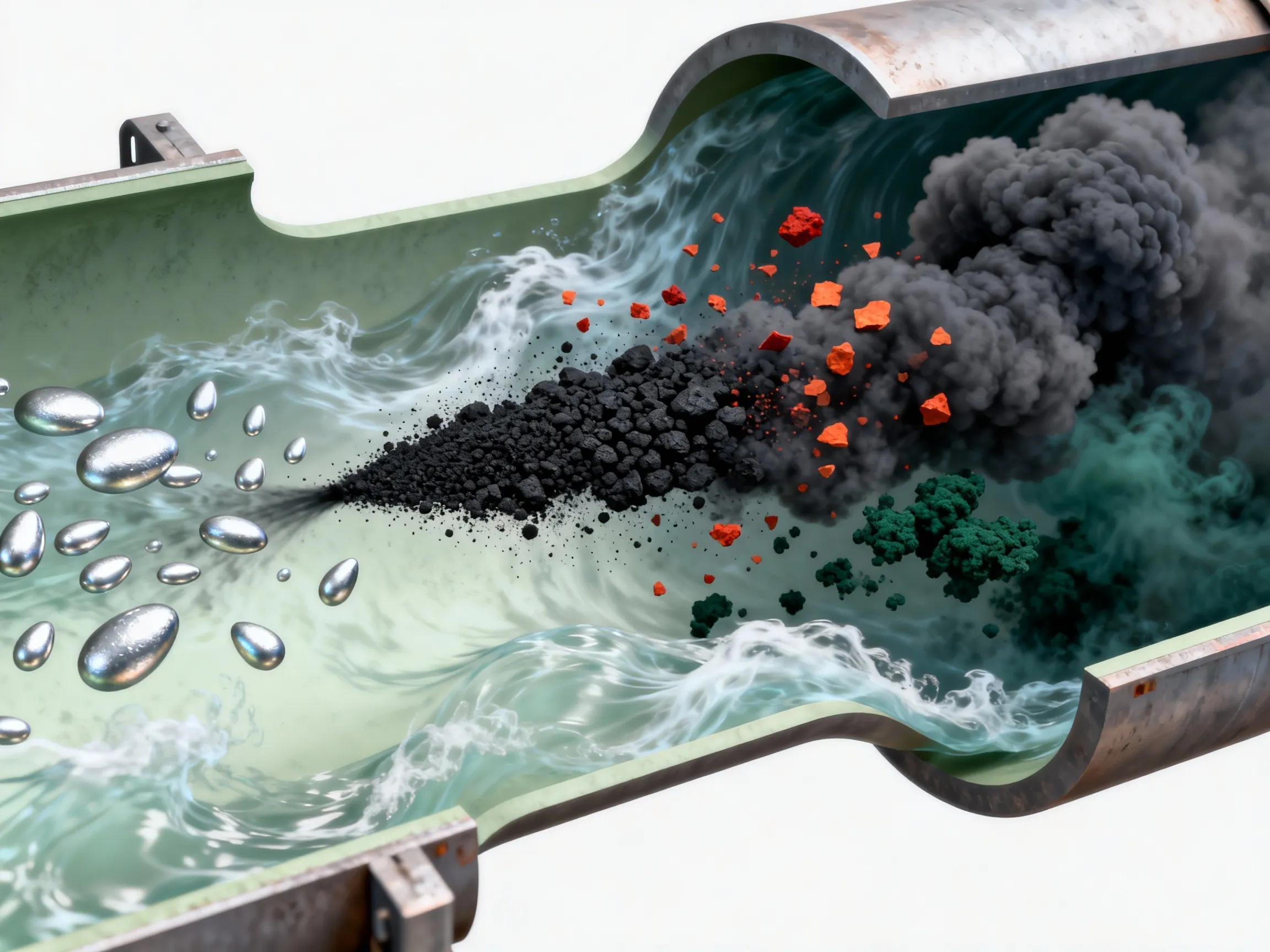

Scene Details

Role of Activated Carbon

Related Product Categories

Brominated (Halogenated) Activated Carbon

The industry standard for coal-fired flue gas, where bromine impregnation enables high capture rates of elemental mercury across various coal types.

Sulfur-Impregnated Activated Carbon

Highly effective in environments with low SO₃ concentrations, utilizing a strong sulfur-mercury affinity for capture, often used in industrial gas streams.

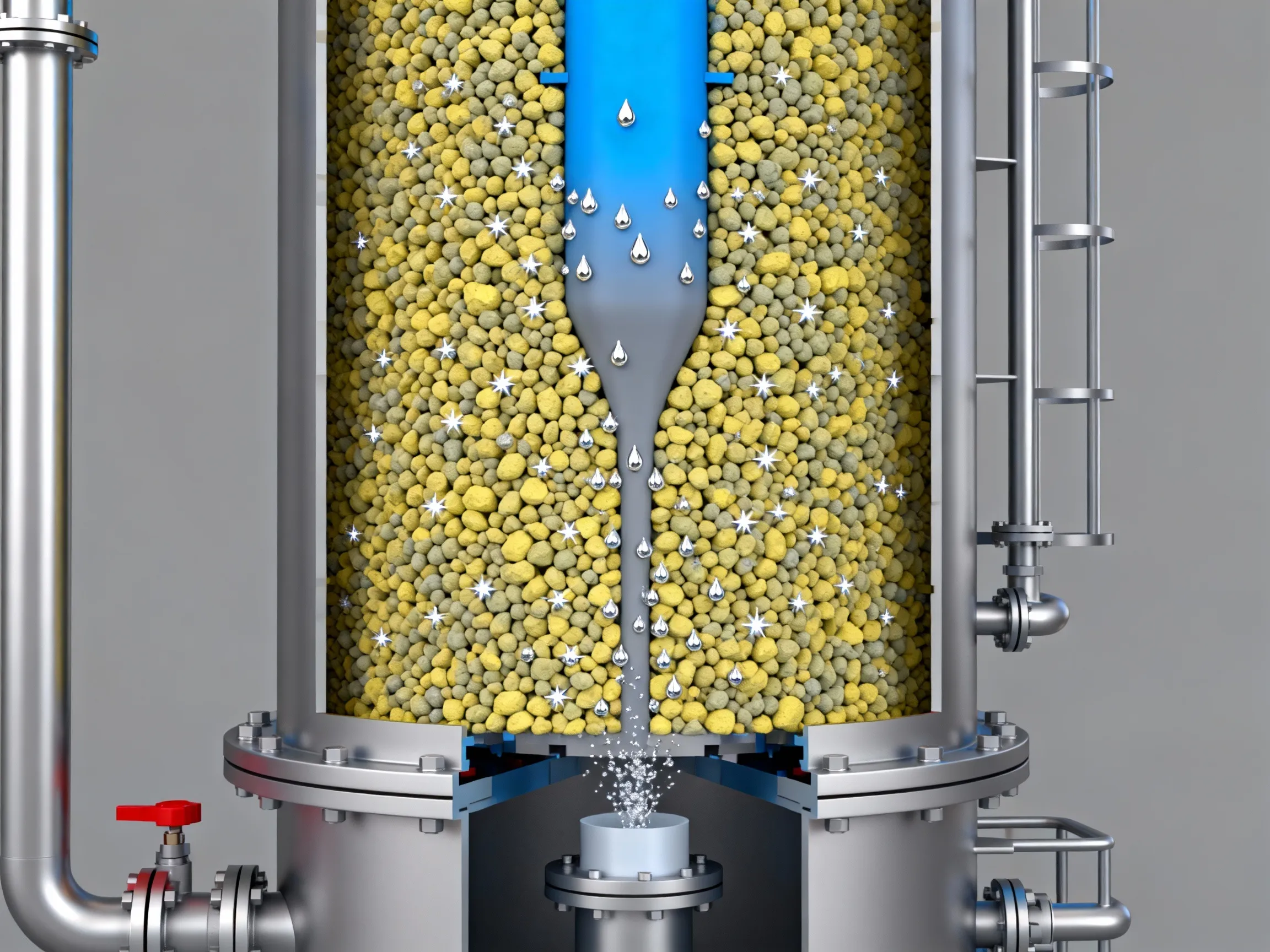

Powdered Activated Carbon (PAC) for ACI

The physical form used in Activated Carbon Injection systems, finely ground for rapid dispersion and maximum contact with flue gas in ductwork.

Bituminous Coal Based PAC

A common and robust base material for impregnation, offering good performance and cost-effectiveness for large-scale utility applications.

Specific Solutions

Activated Carbon Injection (ACI) for Coal-Fired Power Plants

Mercury Control in Waste-to-Energy & Incineration

Industrial Process Gas & Natural Gas Treatment

Why Choose Us

Advanced Impregnation Technology

We master both brominated and sulfur-impregnation chemistries, allowing us to recommend the optimal carbon for your specific flue gas conditions and mercury species.

Proven High Capture Efficiency

Our products are engineered and tested for maximum mercury capacity and fast kinetics, ensuring reliable performance to meet the most stringent regulatory limits.

Full-Scale Application Expertise

We provide comprehensive technical support, from initial pilot testing and modeling to full-scale ACI system design and optimization.

Global Supply Chain for Critical Compliance

We ensure a reliable, high-volume supply of consistent-quality carbon to support your continuous emission control obligations.