DeNOx Activated Carbon

- Home /

- Chemical Activated Carbon /

- DeNOx Activated Carbon

Scene Details

Role of Activated Carbon

Related Product Categories

Impregnated Activated Carbon

Chemically treated with ammonia or other catalytic agents to actively promote the reduction of NOx to nitrogen within its pore structure.

Honeycomb Activated Carbon

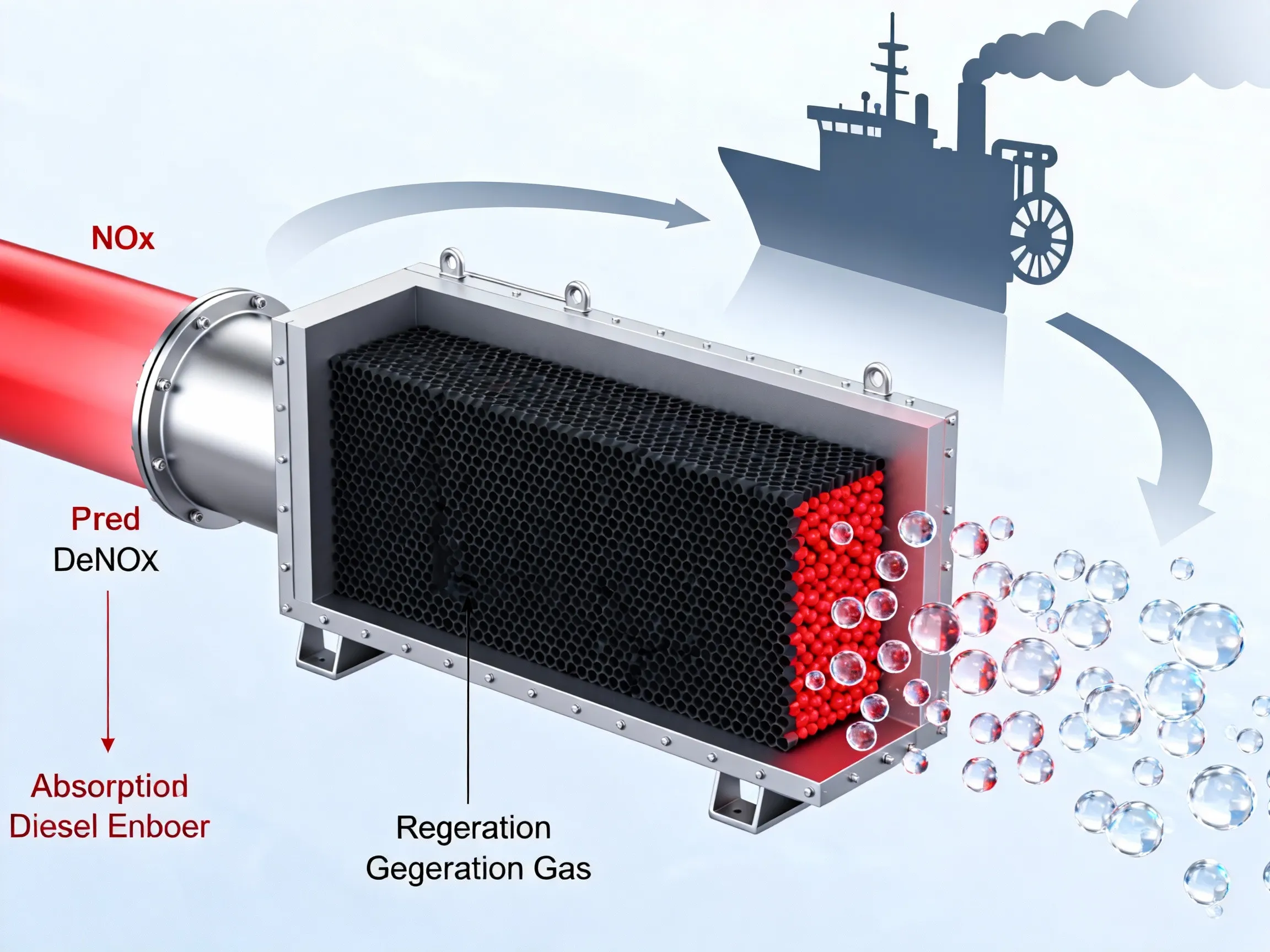

Its monolithic structure offers very low pressure drop, ideal for fitting into compact spaces within flue gas ducts for NOx adsorption.

Pelletized Activated Carbon

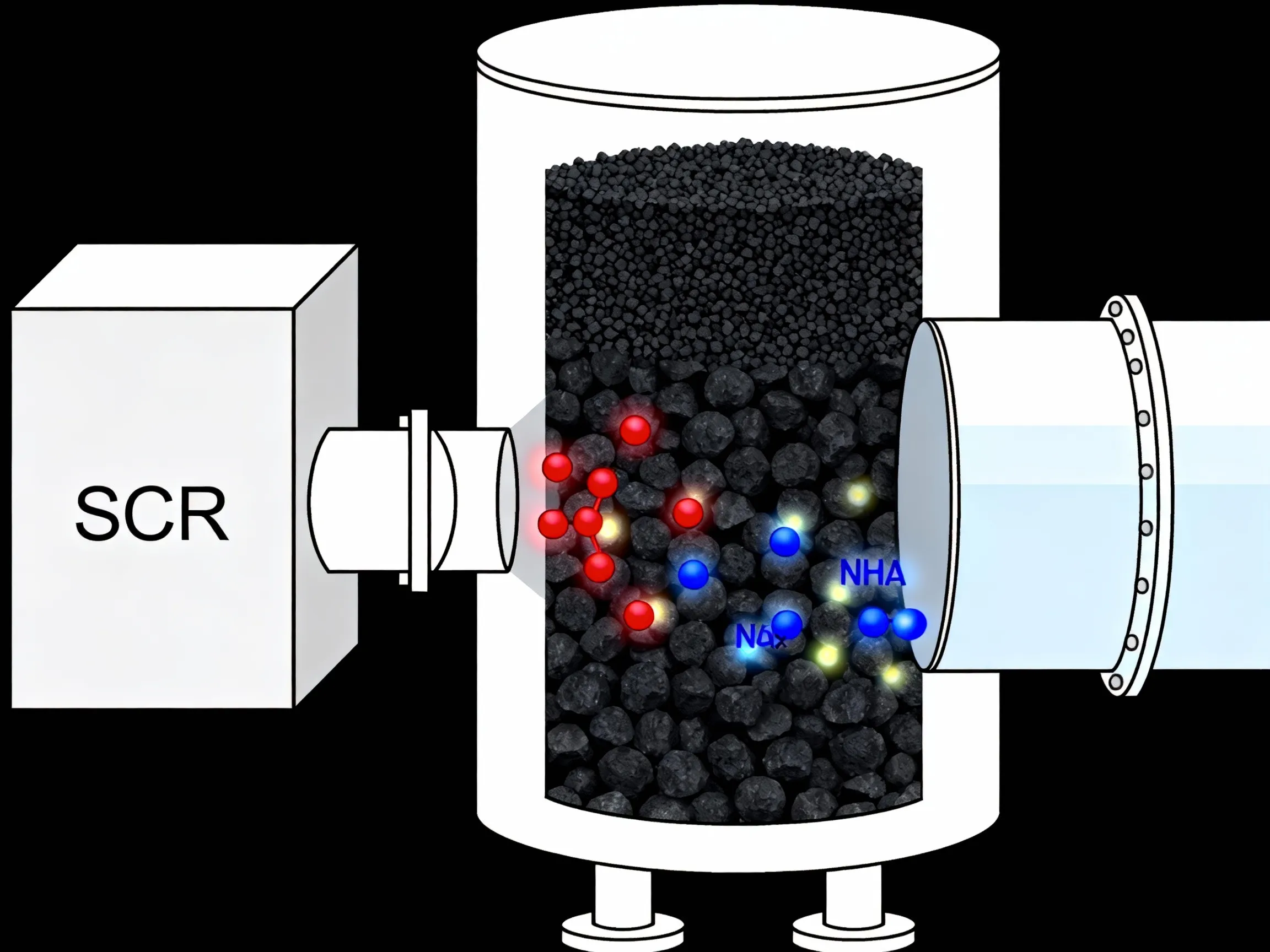

Provides mechanical strength for moving-bed or fixed-bed reactors in DeNOx systems, ensuring consistent gas contact and catalytic activity.

Catalytic Activated Carbon

Engineered with a tailored surface chemistry to enhance the adsorption and conversion of nitrogen oxide molecules.

Specific Solutions

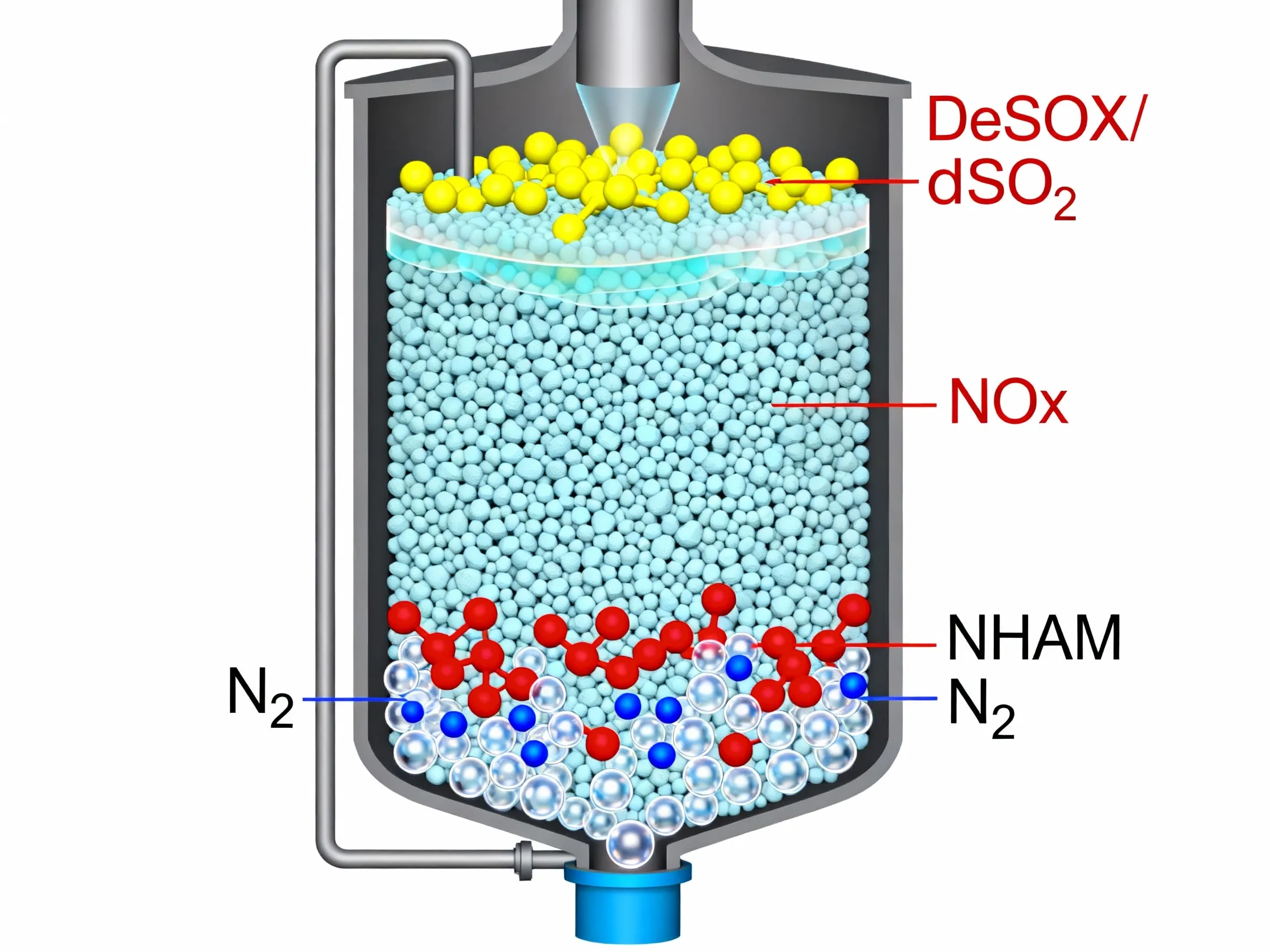

Low-Temperature SCR & Combined Removal Systems

Adsorptive DeNOx for Flue Gas Polishing

Mobile & Marine Source Applications

Why Choose Us

Tailored Impregnation Expertise

We customize chemical impregnations to match your specific gas composition, moisture level, and sulfur species for optimal performance.

High Sulfur Loading Capacity

Our engineered carbons are designed for extended service life and high sulfur retention, reducing change-out frequency and operational costs.

Complete Technical Support

We provide comprehensive assistance with system design, performance modeling, and troubleshooting to ensure your desulfurization success.

Proven Reliability in Critical Streams

Our products are trusted in demanding applications worldwide, from biogas to natural gas, ensuring consistent protection for your assets.