Desulfurization Activated Carbon

- Home /

- Chemical Activated Carbon /

- Desulfurization Activated Carbon

Scene Details

Role of Activated Carbon

Related Product Categories

Impregnated Activated Carbon (for H₂S)

Chemically enhanced with caustic or catalytic agents specifically for high-efficiency hydrogen sulfide removal from moist or dry gas streams.

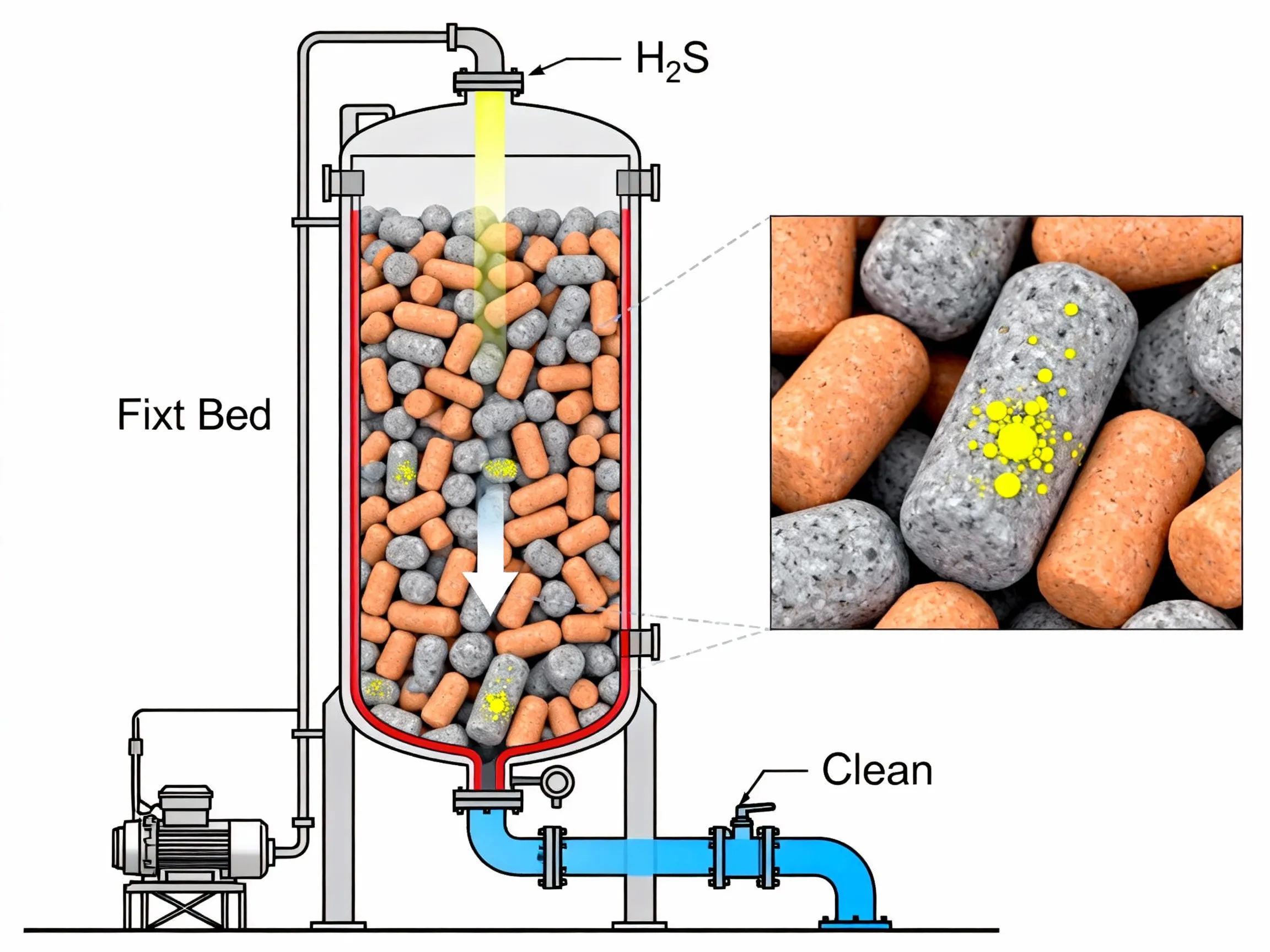

Pelletized Activated Carbon

Offers low pressure drop and high mechanical strength, ideal for fixed-bed reactors in high-flow natural gas or air treatment systems.

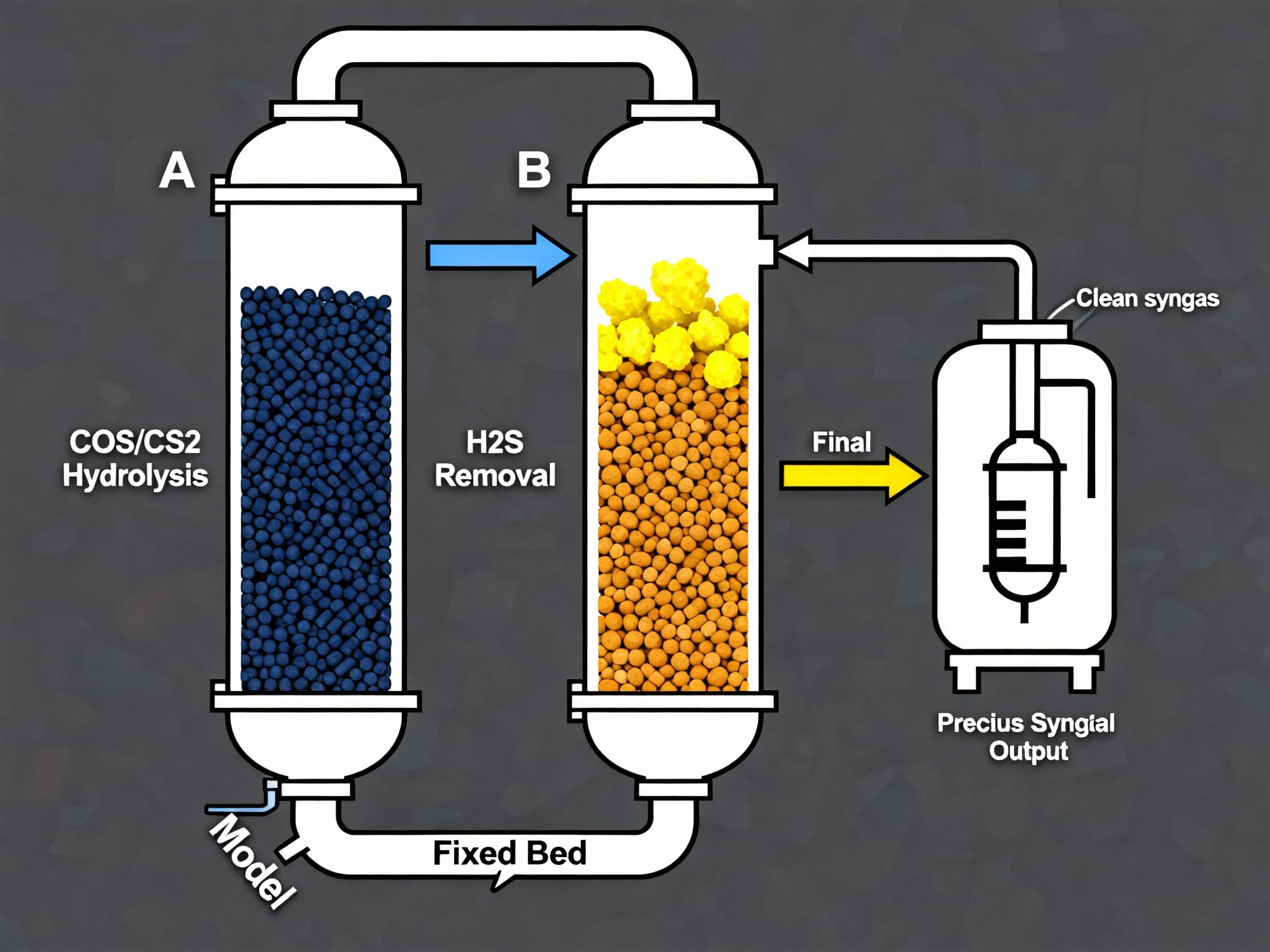

Catalytic Activated Carbon (for COS/CS₂)

Formulated to hydrolyze carbonyl sulfide (COS) and carbon disulfide (CS₂) into H₂S, which is then adsorbed, enabling total sulfur removal.

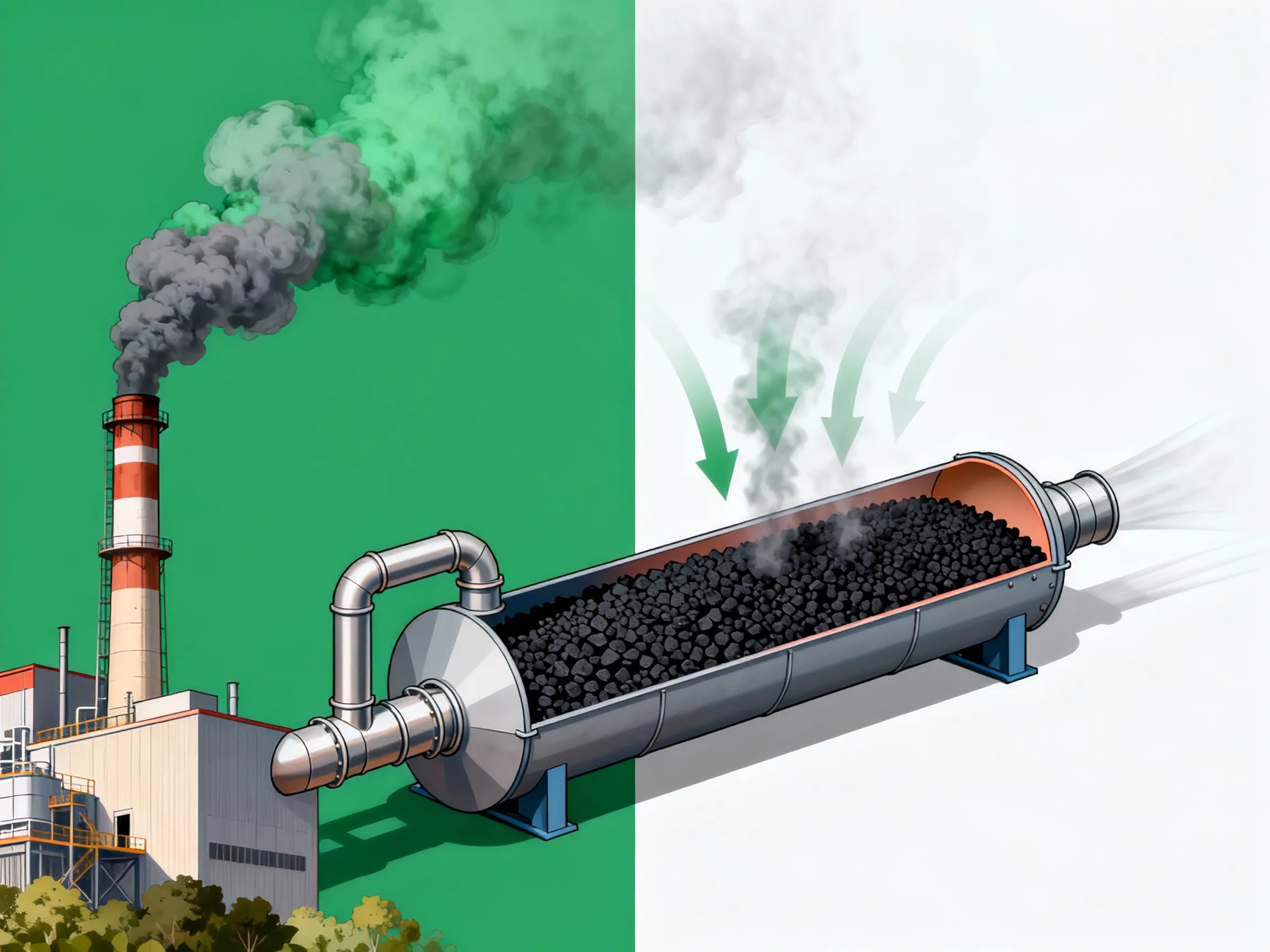

Bituminous Coal Based GAC

Provides a robust and cost-effective substrate for impregnation, commonly used in large-scale desulfurization applications.

Specific Solutions

Natural Gas & Biogas Sweetening

Industrial Air & Odor Control

Syngas & Process Gas Purification

Why Choose Us

Tailored Impregnation Expertise

We customize chemical impregnations to match your specific gas composition, moisture level, and sulfur species for optimal performance.

High Sulfur Loading Capacity

Our engineered carbons are designed for extended service life and high sulfur retention, reducing change-out frequency and operational costs.

Complete Technical Support

We provide comprehensive assistance with system design, performance modeling, and troubleshooting to ensure your desulfurization success.

Proven Reliability in Critical Streams

Our products are trusted in demanding applications worldwide, from biogas to natural gas, ensuring consistent protection for your assets.