Impregnated Activated Carbon

- Home /

- Impregnated Activated Carbon

Classification Introduction

Product Advantages and Characteristics

- The chemical enhancement is due to the presence of chemical agents that can interact with target contaminants, allowing for the removal of compounds unable to be bound by standard carbon.

- Catalytic conversion allows for the safe transformation of hazardous contaminants into less hazardous products via oxidation or reduction.

- The product has been engineered to have a very high level of specificity when it comes to capturing certain gases and vapours depending on the chemical agents used during production.

- This enhanced capacity for adsorption is the result of combining physical adsorption with chemical reactions to achieve maximum removal efficiency of problematic pollutants.

Why Choose Us

Manufacturing

We guarantees that all our impregnated carbon products have the Same consistent chemical distribution and performance & quality standards by utilizing unique manufacturing processes and properly administering quality control.

Sales

A large variety of impregnated carbon products that provide us with the flexibility to develop custom-made solutions to remove multiple contaminants for a diverse group of industries.

Technical Support

We offer expert technical support in determining the appropriate type of impregnated carbon, as well as developing/implementing optimized operating parameters, to ensure the best production efficiency possible.

Relevant Application Scenarios

Chemical

Mercury Removal

Impregnated carbons have been created specifically to eliminate vapor-phase mercury found in flue gases generated by power plants and other industrial processes.

Desulfurization

The process of using a chemical to remove hydrogen sulfide and other sulfur compounds from the gas stream creates a chemical reaction with the impregnated agents.

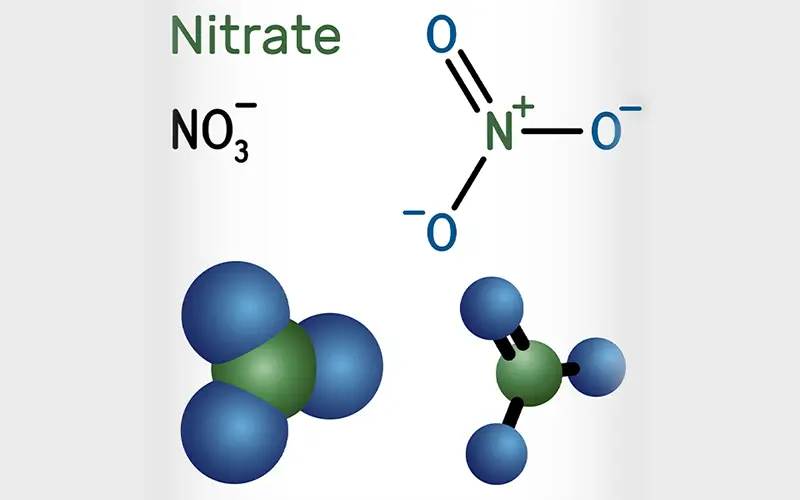

DeNOx

By catalytically reducing nitrogen oxides, impregnated catalytic components can be used to help reduce the nitrogen oxides emitted from exhaust streams

Air / Gas Treatment

Industrial Gas Waste Treatment developed specifically to target and remove specific toxic gas and chemical weapons from industrial waste gas and ventilation systems.

Special impregnated carbons have been created to create a solution to the problem of eliminating hydrogen sulfide and other corrosive vapors from the biogas created during the treatment of wastewater and converting it into energy.

Personal Protection Classifications

Mask Used by military, industry, and emergency response personnel, the mask allows for the maximum level of protection against a wide variety of different types of dangerous gases and chemicals.