Honeycomb activated carbon

- Home /

- Honeycomb activated carbon

Classification Introduction

Product Advantages and Characteristics

- Low pressure drop structure requires very little energy to push air past (ventilation and exhaust).

- Rigidly monolithic, will not break down or generate dust as a result of vibration or airflow.

- Large geometric surface area maximises effectively contaminated surface area between air streams and adsorbent surfaces.

- Rigid and available in standard sizes for easy installation and replacement.

Why Choose Us

Production

Production we ensure high quality products, with uniform cell density, good adsorption capacity and consistent mechanical strength, through extrusion and controlled activation techniques.

Sales

Sale we produce and hold stock of honeycomb blocks of standard and custom sizes at highly competitive prices.

Service

Service we provide back-up technical assistance in all system areas, including design, set-up and performance maximization.

Relevant Application Scenarios

Air / Gas Treatment

Industrial waste gas treatment

Removes VOCs, solvents, and toxic gases from manufacturing waste streams with high efficiency and low energy consumption.

Air purifying

Purifies indoor air in commercial buildings, hospitals, and public spaces by continuously removing airborne contaminants and odors.

Bio odor control

Effectively neutralizes organic odors from wastewater treatment plants, agricultural facilities, and food processing operations.

Biogas

Purifies biogas by removing siloxanes and sulfur compounds, protecting engines and upgrading gas quality for energy recovery

Chemical

Desulfurization

It removes sulfur compounds from gases and liquids, reducing corrosion and emissions.

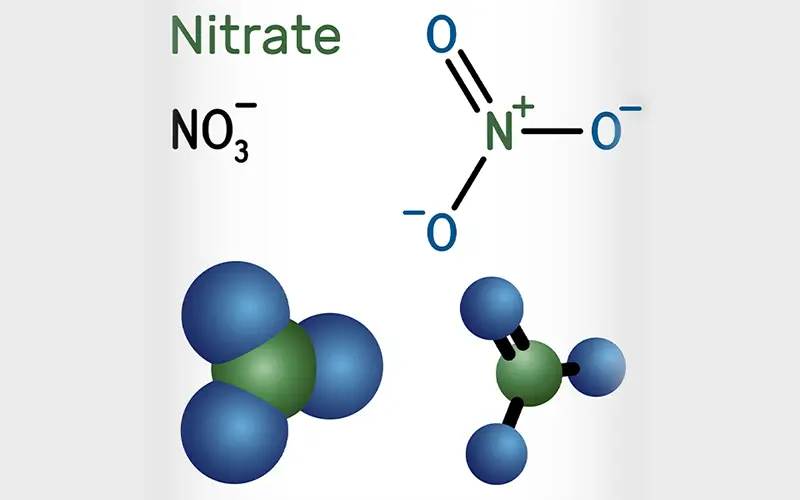

DeNOx

GAC adsorbs nitrogen oxides from exhaust streams, aiding in air pollution control.

Mercury Removal

It captures mercury from flue gases and wastewater, mitigating environmental hazards.

Catalytic

GAC serves as a catalyst support in chemical reactions, enhancing process rates and selectivity.